Problematic soils make up about 70% of the route.

During the construction of the underwater tunnel of Jingtan on the Ningbo–Zhoushan railway line in China, a self-developed saturated pressure system for the tunnel boring machine, unofficially named the "deep-water spatial station," was used for the first time.

The system successfully completed its first high-pressure intervention at a depth of 75 meters on the Ningbo side. The work was carried out continuously for 22 days, during which 46 cutters were replaced, exceeding the traditional safe limit of 60 meters for pressure interventions.

The total length of the Jingtan underwater tunnel is 16.18 kilometers, of which 11.21 kilometers is the underwater section being bored by the tunnel boring machine. The construction is characterized by exceptional geological complexity: there are 24 transitions between soft and hard rocks, with problematic soils making up about 70% of the route.

The maximum rock strength reaches 191 megapascals, which is more than six times the strength of ordinary concrete. The maximum depth of the tunnel is 78 meters, and the peak pressure of the water-soil environment is 8.5 bar. The Yongzhou TBM is equipped with 308 cutters, including 30% more disc cutting elements designed for breaking hard rocks than in standard configurations.

Classic interventions in the operation of tunnel boring machines using compressed air are usually limited to depths of up to 60 meters. Under high-pressure conditions, the effective working time is about 40 minutes per day, while the decompression process takes more than four hours. Additionally, workers are at increased risk of nitrogen narcosis, oxygen toxicity (hyperoxia), and decompression sickness, making frequent cutter replacements at great depths virtually impossible.

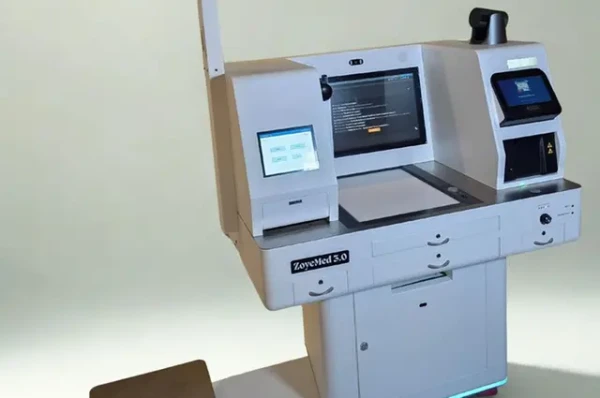

Developed over three years, the new system combines saturated immersion technologies used in deep-water work with tunnel boring construction. Workers undergo compression once, reaching gas saturation, after which they can remain and work at the same depth for a fixed decompression time.

The system includes living, transport, and control modules that allow personnel to be under pressure equivalent to that of the seabed and to regularly move to the face of the tunnel boring machine for maintenance and cutter replacement.

All key subsystems—including pressure control, gas system, and emergency supply—are developed and manufactured domestically. The maximum working depth in saturation mode can reach 100 meters.

To date, the Yongzhou TBM has passed more than 3,000 meters, completing over 60% of the tunneling work.