The new plant will create 1,000 jobs.

This is the story of how a small family business in the European Union grew into a global player changing the rules in the ultra-competitive sector of 'green' steel. A technological challenge in Europe.

Founded in La Coruña, Spain, Russula Group is a global player that has designed 130 steel mills and treatment plants in 35 countries.

To set an example, the company will soon begin construction of its own ultra-efficient 'green' steel plant in Central Spain. The initial investment will be €1.6 billion. The main raw material will be black scrap. The plant will be powered by renewable sources, including 'green' hydrogen. Managers claim that the CO₂ emissions of this steel will be 98% lower than those of conventional steel mills.

"We believe that the steel industry is responsible for nearly 10% of all greenhouse gas emissions in the world. Therefore, we understand that the transition to these new technologies is extremely necessary, as they can save millions of tons of CO₂," says Fernando Pessanha, Chief Strategist at Hydnum Steel. "For example, at our facility, the amount of reduced CO₂ is comparable to the total emissions of all cars in a city like Madrid. This is a colossal volume, and it is crucial to accelerate the ecological transition."

In the first phase, the plant is expected to produce 1.6 million tons of flat products, with plans to double that volume later. The plant will create about 1,000 direct jobs, and after reaching full capacity, also thousands of indirect jobs.

According to management, sustainable innovation is the key to a competitive future for European metallurgy.

"The automotive industry, infrastructure, and renewable energy sources have already made commitments to decarbonization — which means the entire value chain must be decarbonized," says Daniel Sanchez, Chief Operating Officer of Russula Group. "The key role of steel is the complete decarbonization of the supply chain."

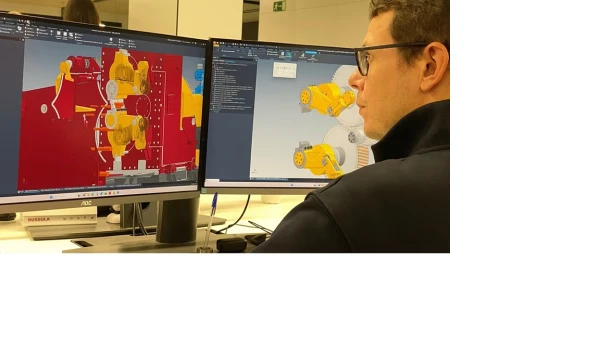

Engineers make up 60% of the company's staff. They are completing work on the new steel mill while simultaneously managing dozens of projects around the world.

Leave a comment