In the electronics field, it is used in the production of filaments.

Peru ranks second in the world in molybdenum production, which is a result of the growth in copper mining, where this metal is obtained as a byproduct.

According to the U.S. Geological Survey, in 2024 our country produced 41,000 tons of molybdenum, second only to China with 110,000 tons. Chile ranks third with 38,000 tons per year, followed by the United States with 33,000 tons per year and Mexico with 17,000 tons per year.

At the regional level, according to the Minem mining industry statistics bulletin, from January to July of this year, the province of Tacna leads in production with 5,991 thousand tons. It is followed by Arequipa with 5,477 thousand tons, Moquegua with 5,197 thousand tons, and Ancash with 2,486 thousand tons.

As for the companies with the largest contribution during the same period, Southern Perú Copper Corporation leads with a share of 37.1%, followed by the mining company Cerro Verde S.A.A. (24%), Anglo American Quellaveco S.A. (12%), and Antamina (10.9%).

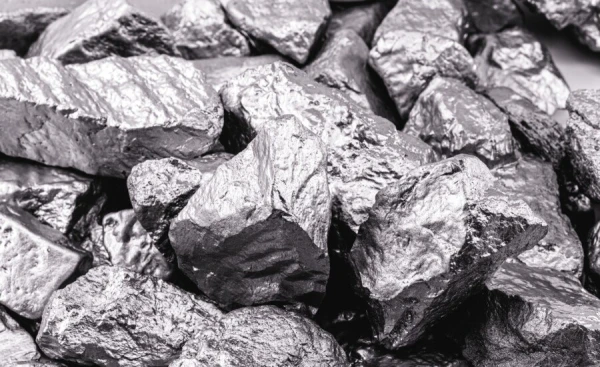

Molybdenum is a transition metal with an outstanding ability to withstand high temperatures without losing corrosion resistance. Due to these properties, it has become an indispensable component in various industries.

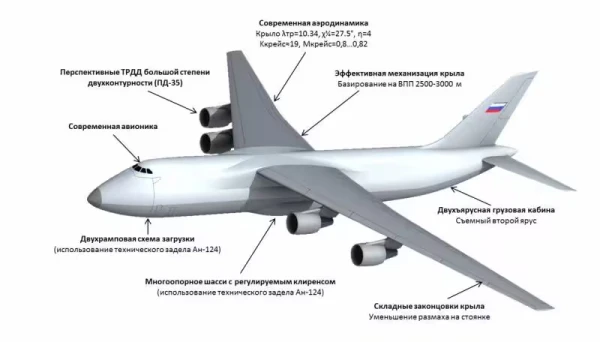

One of its most important applications is in the production of various types of stainless steel and high-strength steel. Adding small amounts of molybdenum enhances their wear and corrosion resistance, making them ideal for chemical plants, oil refineries, and offshore platforms.

Molybdenum also helps improve fuel quality and reduce pollutant emissions, as it is necessary in the hydrotreating process, which lowers sulfur content. Additionally, it plays a crucial role in the development of catalysts for the oil and gas industry.

In the electronics field, it is used in the production of filaments for light bulbs and LCD displays, as well as in electrical and semiconductor contacts. Its high electrical and thermal conductivity, combined with heat resistance, makes it an ideal material for high-precision components.

Leave a comment