The efficiency of the combine's work is 99% of weeds destroyed.

One of the world leaders in graphics processing units, Nvidia, and the developer of AI-based agricultural robots, Carbon Robotics, have joined forces in the fight against weeds, resulting in the creation of the LaserWeeder G2 robot.

This tractor-towed device boasts significant computing power and 36 high-resolution cameras for identifying and eliminating weeds using 24 diode lasers, each with a power of 240 watts. Over the past seven years, one and a half hundred farmers in 14 countries have already utilized the services of this "Terminator."

The robot is capable of dealing with 10,000 weeds per minute or 600,000 weeds per hour. It is designed to process between 2 to 4 hectares per hour, surpassing the capabilities of a crew of 75 people. The efficiency of the LaserWeeder G2 is 99% of weeds destroyed.

The LaserWeeder G2 has undeniable advantages over herbicides. Firstly, the high-precision robot is much safer, and secondly, weeds do not develop adaptation to this form of treatment.

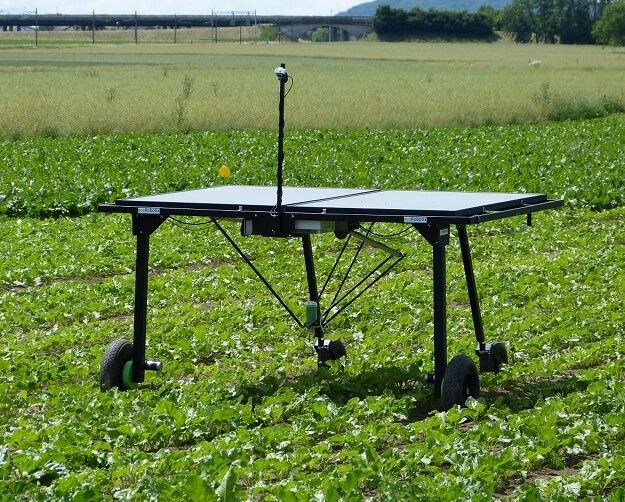

The lightweight weeding robot Ecorobotix (Ecorobotix company, Switzerland) is the first fully autonomous machine for economical weeding of row crops, meadows, and cover crops, adhering to environmental protection principles. Weighing only 130 kilograms, it minimizes soil compaction and operates on solar energy for up to 12 hours a day without a human operator.

The fully autonomous drone is equipped with a lightweight GPS tracker and a range of sensors. To set targets and spray weeds, the robot uses a complex camera system. Precise manipulators allow for 90% less herbicide use through micro-spraying, while also being 30% cheaper than traditional processing methods. The machine can process three hectares of land per day. The upper part of the robot is covered with photovoltaic solar panels, providing a stable energy supply.

In terms of energy consumption, the robot is fully autonomous even in cloudy weather. It adjusts its speed to the concentration of weeds and is most suitable for use in fields with low to moderate weed concentration. It is recommended to deploy this machine in the field after the initial standard herbicide application to replace subsequent treatments, thus saving a significant amount of chemicals. The machine can be controlled and configured using a smartphone app.

A Belgian robotics company has launched a fully autonomous strawberry-picking robot called Rubion. The machine can move through greenhouses or agricultural tunnels, and thanks to optimal ripeness detection and even pressure distribution, it can identify ripe strawberries and collect them without damage or "bruises." After harvesting, the system weighs the berries and places them in a box. The machine exhibits the behavior of an experienced picker, can sort strawberries by ripeness and size, and package them into different categories. Rubion is capable of predicting the next harvest by analyzing the current collection and helping farmers plan their operations effectively.