Technologies of the near future are based on innovative coatings.

The German company Dcubed is preparing to test its ARAQYS technology in field conditions – that is, in open space. It is designed to create solar panels that serve as the primary energy source for almost all commercial satellites. Instead of transporting and installing panels from Earth, they will be manufactured directly in orbit.

The efficiency of solar panels directly depends on their area, which is why they always represent massive structures. To fit such a structure in the cramped space of a rocket's payload module, it has to be made foldable. This means that along with the payload in the form of the panel itself, a mechanism for deploying it in orbit must also be transported into space. This mechanism is also not cheap – it must reliably withstand the overloads during flight; otherwise, the panel will not unfold.

The principle of ARAQYS is based on the use of a flexible ultra-thin photosensitive coating that generates energy when exposed to sunlight. It is only necessary to create a frame for it, which can be done in orbit using a 3D printer. A special resin is used that adheres to the material of the future solar panel and hardens under ultraviolet light.

During the first test in space, a trial version of the frame measuring 60 cm will be printed. Then, in 2027, a demonstration model of a 1 m long panel with a power output of 2 kW will be created. If everything goes well, the technology will be commercially applied. Its creators are also considering that with the help of 3D printing in space, other engineering structures can be created – for example, antenna arrays.

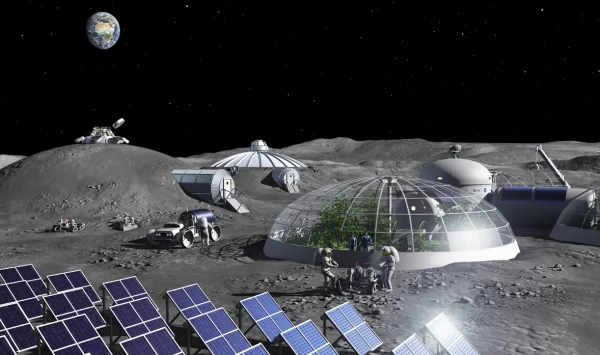

Researchers from Italy and Germany have also developed solar panels that are almost entirely made from materials available on the Moon. The photovoltaic elements consist of thin films of perovskite – a light-absorbing material of terrestrial origin, placed inside "lunar glass" (made from the mineral anorthosite, which is widely distributed on the lunar surface). Such batteries will provide future lunar bases with renewable energy, reducing supplies from Earth by 99.4%.

The new panels are radiation-resistant thanks to two-millimeter layers of "lunar glass" that protect the perovskite films without interfering with their ability to capture sunlight. The panels convert 10–23% of solar energy into electricity, which is lower than traditional panels based on gallium and indium (about 30%), but their advantage lies in their lightness and low cost of production on the Moon. This solves the problem of high delivery costs: one kilogram of cargo to the Moon costs about one million euros, while the new batteries require almost no terrestrial materials.

The technology will allow the construction of large lunar bases for 200 or more people, significantly reducing energy supply costs. Scientists note that their development is part of global efforts to create systems that utilize lunar resources for the production of energy, water, and oxygen.

Leave a comment