The capacity utilization of manufacturing facilities in Latvia currently stands at 75%, but the level of productivity increasingly lags behind the average in the European Union, writes Bank of Latvia economist Agnese Puke on the Makroekonomika.lv portal, reports LETA.

A slight lag in capacity utilization indicates structural problems related to poorly utilized small and low-profit enterprises, notes the economist. Other structural challenges hindering productivity growth include weak innovation, outdated capital, insufficient investments, and funding in low-tech industries, Puke points out.

She emphasizes that the directions for improving productivity are well known — enhancing the quality of capital, developing high-tech sectors, and scaling up enterprises. Achieving this requires consistent action at both the business level and in state and financial policy.

According to Puke, low utilization means that capital and labor resources are not being fully utilized, which reduces productivity.

The economist explains that production capacities are not static — the intensity of capital and labor adjusts to demand, costs, and technological development. In practice, achieving 100% utilization is impossible and not economically optimal. A level of 85–90% is considered quite high, as exceeding it can lead to overloading and increased costs.

The highest level of capacity utilization among EU countries was recorded in the Czech Republic in June 2008 — 90.8%, during a period of economic overheating before the global financial crisis, which is quite indicative, the economist notes.

According to Puke, achieving maximum utilization is limited by three groups of short-term factors and one long-term factor. The short-term factors include technological and logistical constraints, organizational and staffing difficulties, as well as market and strategic considerations.

The long-term structural factor is hysteresis. Puke explains that in macroeconomics, hysteresis describes a situation where a short-term economic shock has a lasting or even permanent impact on output and productivity.

If capacity utilization significantly decreases during a shock, companies postpone investments, capital accumulation slows down, and spending on research and development is cut, the economist notes. These decisions lead to a structural loss of productivity that persists even after demand recovers. Additionally, some enterprises go bankrupt during a crisis, change their profile, or lose markets and access to raw materials — and these production capacities do not recover in the growth phase.

Puke reminds us that after the financial crisis of 2008, the global economy, Europe, and Latvia were shaken by new shocks — the annexation of Crimea by Russia in 2014, the Covid-19 pandemic (2020–2021), the energy crisis (2021–2022), Russia's full-scale invasion of Ukraine since 2022, and the subsequent sanctions.

This caused short-term disruptions in demand and shortages of raw materials and components. During periods of faster growth, the issue of labor availability became more acute, which also forced adaptations in production processes and investments in automation.

Economic cycles and challenges in ensuring optimal utilization have structurally changed the industry, periodically pushing development backward, like going down the stairs in a board game, while simultaneously creating opportunities for adaptation and new businesses, Puke explains. Despite fluctuations, Latvia is gradually approaching the average level of capacity utilization in the EU, which reached nearly 85% in the "fat years," but has since weakened under the influence of crises.

Current capacity utilization in Latvia stands at 75%, which, according to the economist, leaves room for growth to the EU average (78%) and even beyond.

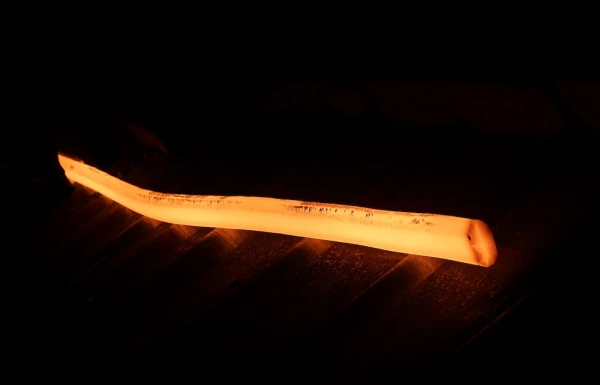

Puke acknowledges that the lag is observed in most industries. Among the few with above-average EU indicators are clothing manufacturing, woodworking, metalworking, and the furniture industry. The greatest lag is in the production of vehicles and paper. Both sectors have a negligible weight in the manufacturing industry — 1.7% and 1.3%, respectively.

Although capacity utilization in Latvia's manufacturing industry is steadily increasing and approaching the EU average, the productivity of the sector is increasingly lagging behind. According to Puke, this indicates structural problems that hinder production efficiency even with relatively high resource utilization.

Puke identifies four key reasons for the lag in productivity — the dominance of small and inefficient enterprises, a lack of innovation, outdated capital, a shortage of investments in industry, and a focus on low-tech and low-knowledge sectors.

The economist notes that small enterprises are hindered from being more productive and providing high production capacity by factors such as limited financial resources, modest investment opportunities, low diversification, small order volumes, demand fluctuations, and a lack of managerial, organizational, and human resources.

Puke also acknowledges that according to a survey by the European Investment Bank, the level of innovation in Latvia is the second lowest in the EU, with a significant lag behind leading countries. Latvian enterprises do not stand out for novelty either at the level of individual companies or on a state or global scale.

Puke's analysis shows that the manufacturing industry in Latvia accounts for only one-tenth of all investments, making the country one of the last in the EU in this regard.

"The problem of outdated capital was embedded in us from the cradle — during the transition from a planned economy to a market one, with radically different technologies, levels of automation, and completely different demand. Production had to be built almost from scratch. Due to a lack of funding, this replacement was neither quick nor easy. Moreover, the problem of outdated capital was broader than just buildings and equipment — the housing stock, infrastructure, and knowledge were also outdated," writes Puke.

According to her, expanding borrowing opportunities created new rules of the game, paving the way for a new era of growth. Unfortunately, the significant investment boom in the manufacturing industry coincided with investments in other sectors, leading to rising costs, economic overheating, and a severe shock during the 2008 crisis. Investor activity halved, distrust in borrowed funds increased, resulting in many relying only on their own resources or "safe" EU fund means. Creditors themselves also became more cautious. Puke acknowledges that this approach has limited faster growth in the manufacturing industry.

"If we once entered the competitive environment of a free market with weak capital and its low adaptability to demand, and after 30 years lagged behind in terms of new investment volumes, it can be concluded that capital and its development in the Latvian manufacturing industry remain insufficient for the sector to become a driving force of the economy," writes the economist.

Puke concludes that a sustainable breakthrough cannot be achieved simply by "working harder" or hoping for increased capacity utilization — it is necessary to improve the quality of capital, develop high-tech segments, and promote the growth of enterprises so that productivity in Latvia can reach a higher level.

Leave a comment